R&D Center

Dongwon Systems is preparing for the future of the global packaging

industry that will inspire consumers and make a healthier planet.

Research & Develop New Meterials for Tomorrow

Dongwon Systems operates the Technology Research Center in order to remain

competitive in terms of sustainable products and customer satisfaction.

Technology Research Center

The aim of the research center is to help Dongwon Systems continue to

expand beyond the food market and improve its competitiveness in

manufacturing by obtaining new technologies in new materials and building

up a highly efficient R&D structure. Research divisions for each main

business area within the center promote expertise through the

departmentalization of development areas.

-

- LIB Battery Materials R&D Tech Center

- Development LIB Materials

- - Cathode Foil

- - Battery Can

- - Cell Pouch

- Development Material components for LIB cells

-

- Aluminum (Al) Lab

- NEW products from rolled Al

- Foil coating products for secondary cells

- New businesses in Al processing

-

- Resins Lab

- Industrial films

- Protection films for electronics

- New hygiene products

-

- Upgrading Pet Food Packaging Products

- Demand for pet food packaging is high in Western countries, and in order to meet this demand we have developed TEAR, a packaging product that features an applied use of fishing lines to make it easy to open. We have also differentiated TEAR from other products by incorporating a new form of zipper. We are planning to develop leather texture packaging and falsification prevention packaging.

- Globalization of Retort Pouches

- Up to this point, our trade transactions of retort pouches have been limited to our affiliates. Through improved product quality, however, we have developed retort pouches that can satisfy the needs of customers and have also globalized Dongwon Systems’ product sales.

-

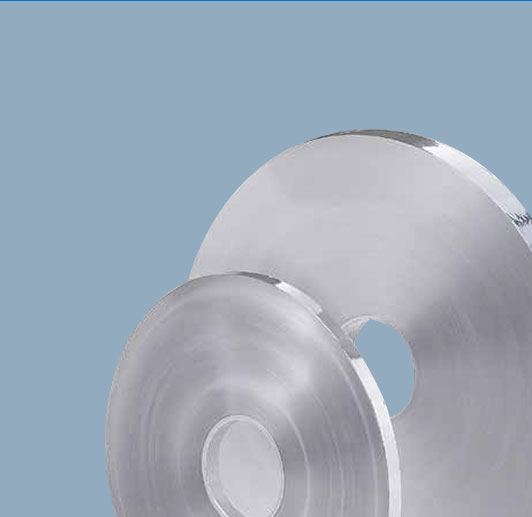

- Development of Ultrathin-Layer Aluminum Foil

- Condensers that are used in electrical parts and electronics possess higher capacity due to the larger surface area of the foil. Through using 4.5 ㎛ ultrathin-layer aluminum foil, we have developed a product with high charging capacity and low deviation in capacity.

- Increasing Market Share Through the Development of Beauty Packaging

- We have completed the development of 3-ply pouches, which are made using laser cutting. Their packaging is made with felt, making it feel like paper.

-

- Development of cathode foil for LIB

- An aluminum (AL) foil is used for the Cathode and a copper (Cu) foil is used for the anode in the LIB. We are mass-producing ultra-thin 9μm AL-Foil used for cathode materials used in LIB and developing products with differentiated technologies such as surface treatment coating technology to increase battery performance and life cycle.

- Development of battery can for LIB

- This mold product is as one of the packaging technologies of secondary batteries and being mass-produced by applying our differentiation technology to 18650, 21700, 4680, coin cell, etc. In order to secure the competitiveness of differentiation of products, we have developed and applied durable mold design technology, deep drawing technology, and surface treatment technology with excellent corrosion resistance.

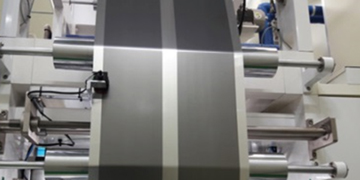

- Development of cell pouch for LIB

- As one of the secondary battery packaging technologies, a multi-layer Li-ion polymer battery case, which is flexible and has high temperature stability and electrochemical characteristics, is being developed, and the surface treatment coating technology, dry lamination technology, and extrusion lamination technology can improve its competitiveness.